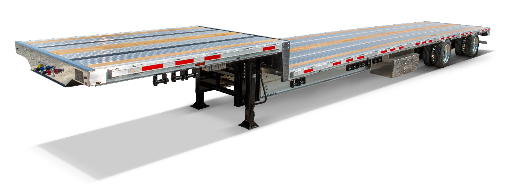

Aluminum Drop Decks

Get The Results You Demand.

Wabash’s aluminum drop decks are high-performing and lightweight. Whether a regional or cross-country haul, these platform trailers are the go-to for low-cost, low-maintenance miles—even for loads with special requirements.

Wabash’s nationwide network of highly trained dealers work alongside you to meet your specific needs. With features designed to increase safety, decrease weight and increase load capacity, these trailers give you results and peace of mind.

Features & Benefits

Superior Main Beam. Lower Maintenance.

The two-piece, welded main beam design eliminates the need for mechanical fasteners by welding on the neutral axis of the main beam where bending stress is minimal. Unlike bolted designs, this main beam has no fasteners that eventually loosen and lead to additional maintenance.

Less Weight. More Freight.

Floor crossmembers weld to the main beam, side rail, and floor to form a super stiff structure, eliminating the need for knee braces for a lighter weight trailer and less maintenance.

Greater Flexibility. More Loaded Miles.

The Lock-Rite® multi-position tie down system offers flexibility to either tie down narrow loads to the center of the trailer or to the outside siderails. This patent-pending design also allows the use of either straps or chains to secure loads.

General

- Length: 28′- 53′

- Width: 96″ and 102″

- Upper Deck: 10′ or 11′

Beam Rating

- 524: 52,000 in 4′ / 55,000 lb in 10′ / 105,000 lb evenly distributed

48′ Base Weight

- 524: 9,203 lb/4,174 kg

Main Beam Design

- Welded, 2-piece, 6061 T6 extruded aluminum ″T″ cross sections

- Beams welded along neutral axis

- Floor sections welded to top flange of main beam

- Top tee extrusion with integral Lock-Rite groove

- Main beam camber cut in lower aluminum ″T″ section

Front End Design

- High tensile steel neck for increased strength

- Bright finish, fabricated aluminum front crossmember

- Center mount glad hands and 7-way on removable access panel

- 1/4″ steel coupler plate welded to neck

- Heavy-duty cross and aft bracing

Rear End Design

- Closed section extruded rear light box

- Three rear stake pockets with extruded pocket protector

- Tubular bumper uprights with flanges for mounting accessories

- Extruded grip surface on top of bumper tube

- Rubber dock bumpers mounted vertically with three bolts

- Bumper assemblies are United States Department of Transportation (DOT) and Transport Canada compliant

Siderail Design

- Extruded box section side rail with integral Lock-Rite groove

- Radius edges to prevent strap damage

- ″LL″ sliding winch track roadside, bolt-on design

- Tumbled aluminum stake pockets on 24″ centers

- Large diameter double pipe spools

- Extruded aluminum rub rail with recessed groove

Crossmember Design and Floor System

- 4-7/8″ aluminum C-channel crossmembers on 16″ centers

- 1-1/4″ hollow core box design, extruded aluminum floor boards with four apitong nailers, two singles outside, double in the center

- Crossmembers welded vertically to siderail and main beam; horizontally to floor

Undercarriage

- Lightweight, formed suspension crossmembers at suspension hangers and air springs

- Bolt-on, lower steel C-channel and strut bracing

- Air suspension with manufacturer′s 5-year warranty

- 121″ tandem widespread axle setting, large bearings, parallel ″P″ spindle wheel ends and axle alignment

Electrical Wiring / Lights

- Air and electrical accessible through removable front plate

- Below deck air and wire routing

- Enhanced visibility lighting system with recessed oval lights

- LED lights, five side marker lights per side, dual function lights correspond with turn signals

- Anti-lock brake system (ABS)

Options

- Additional air and electric configurations

- Additional aluminum components

- Alternate crossmember spacing

- Corrosion prevention packages

- Customized bumper filler plates

- Disc brakes

- Factory installed bulkheads

- Specialized floor packages

- Multiple accessories, freight securement and storage options

- Multiple axle configurations, sliding suspensions and lift axles

- Premium rear features